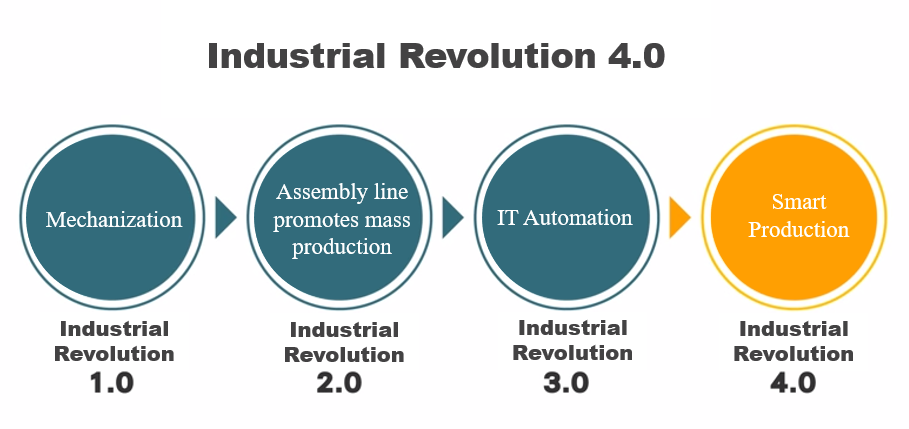

On October 16, 2014, the Industrial Development Bureau of the Ministry of Economic Affairs of Taiwan launched the itsTaiwan version of the Industrial Revolution 4.0, known as the Productivity 4.0 plan. There are two requirements: (1) the use of robots in large quantities; (2) with Industry 4.0 in mind, the production process should be more automated and integrated with Internet of Things (IoT) technology, cloud computing, and real-time information processing.

After the introduction of IoT technology, they were faced with a colossal amount of information collected from manufacturing, service, and technology industries through the means of big data analysis. All industries in Taiwan were required to launch related technologies. It was then promoted to the Executive Yuan where other ministries were invited to participate. On February 16, this year (2015), President Mao of the Executive Yuan announced that the Taiwan version of the “Productivity 4.0 Plan” will be launched. The goal is that within ten years, one person would be able to receive two salaries for finishing three jobs. The plan will be a ten-year period introducing IoT technology, smart robots and big data. It will initially give priority to seven areas: machine tools, metal processing, 3C (computer, communication and consumer electronics), food, medical, logistics, and agriculture.

At the same time, the Industrial Development Bureau officially launched an industrial transformation action plan to promote the upgrading of traditional industries making way for emerging industries. In the process of industrial transformation, there will be major obstacles. Not only does Taiwan have an aging population and a shocking decline in birth rate, but the people have a unique mindset of “late in, early out”. These are all important issues that economic development is still unable to solve.

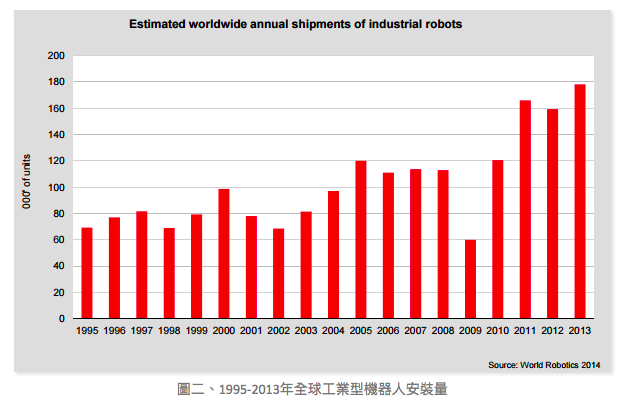

According to the data of the National Development Council, Taiwan’s labor force is being reduced by 180,000 people every year since 2016. Therefore, the policy must consider the issue of productivity and how to use new technologies to solve the changes in Taiwan’s population structure.